| Sign In | Join Free | My benadorassociates.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My benadorassociates.com |

|

| Attribute | Value |

|---|---|

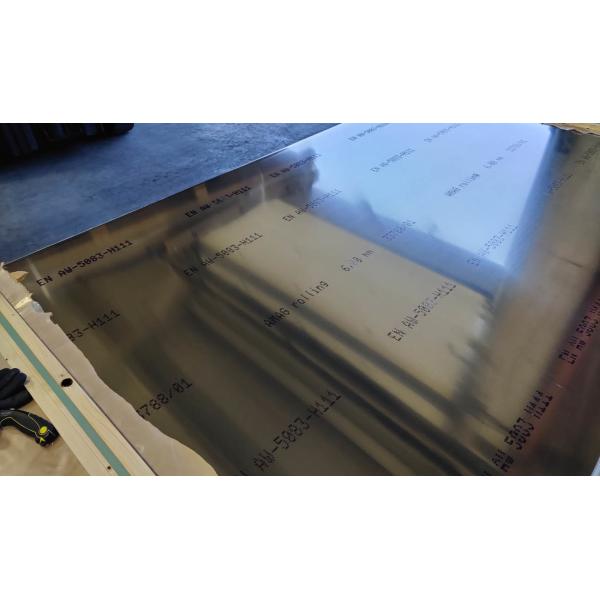

| Type | Aluminum alloy plate |

| Alloy | 5083 |

| Temper | O / H111 /H321 |

| Application | Spacecraft Fuel Tank |

| Width | 800-4300mm |

| Length | 1000mm-38000mm |

| Package | Water-proof Standard Export Package |

| Price Term | FOB, EXW, CFR, CIF etc |

| Code | Name | Brand |

|---|---|---|

| a | Aluminum ingot melting furnace | GAUTSCHI (Switzerland) |

| b | 2800mm width single stand cold rolling mill | SMS Group (Germany) |

| c | 4 continuous hot rolling mills | SMS Group (Germany) |

| d | Heavy crop and dividing shear | SMS Group (Germany) |

| e | Coil material annealing furnace | SMS Group (Germany) |

| f | All automatic three-dimensional elevated warehouse | Dematic (USA) |

| Property | Value |

|---|---|

| Density | 2650 kg/m3 |

| Melting Point | 570°C |

| Modulus of Elasticity | 72 GPa |

| Electrical Resistivity | 0.58 x 10-6 Ω.m |

| Thermal Conductivity | 121 W/m.K |

| Thermal Expansion | 25 x 10-6/K |

|

|

High Strength Corrosion Resistance Aluminum Plate 5083 Spacecraft Fuel Tanks Images |